Turbochargers cast into the cylinder head seem to be next. Why? Reduced costs being the main reason:

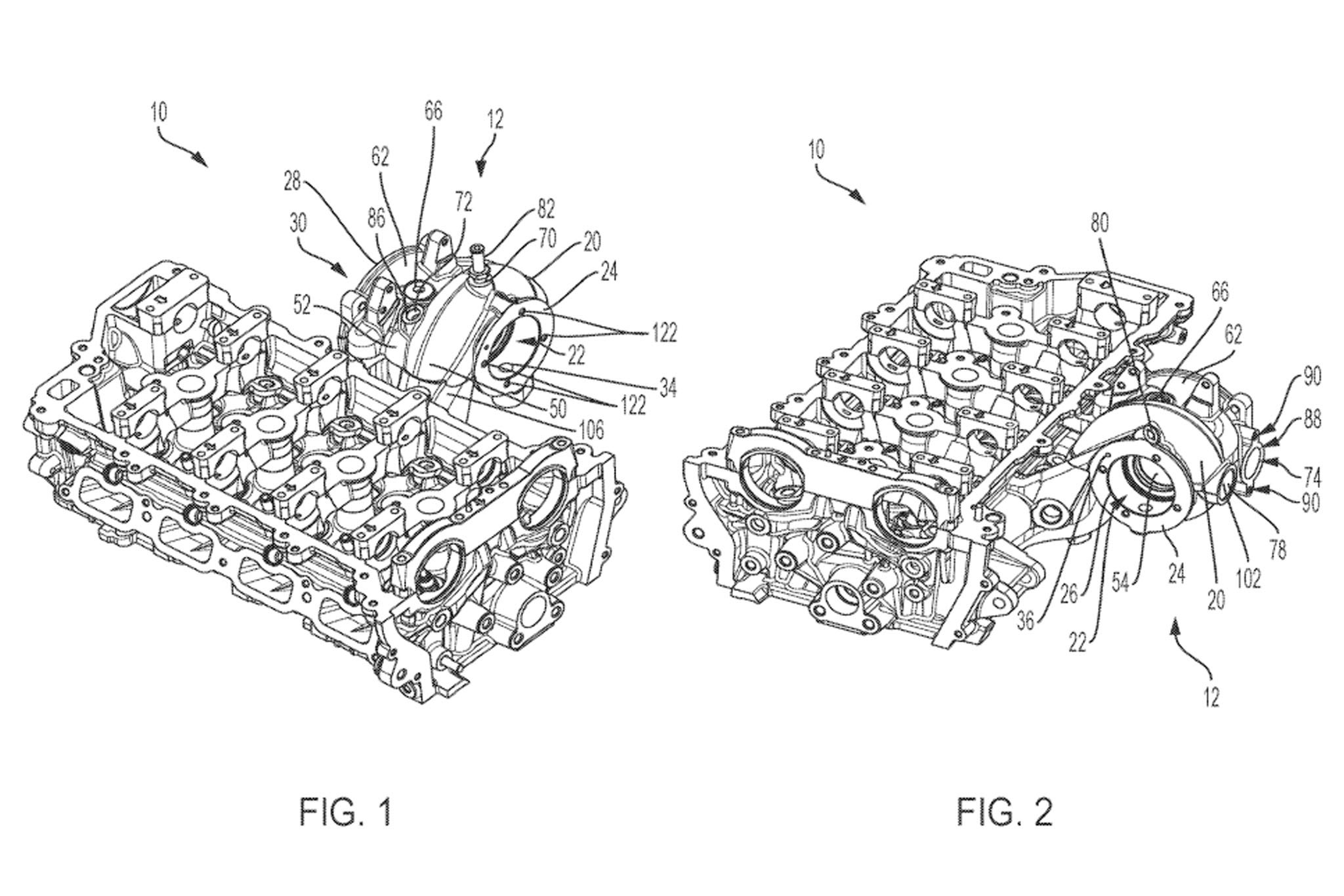

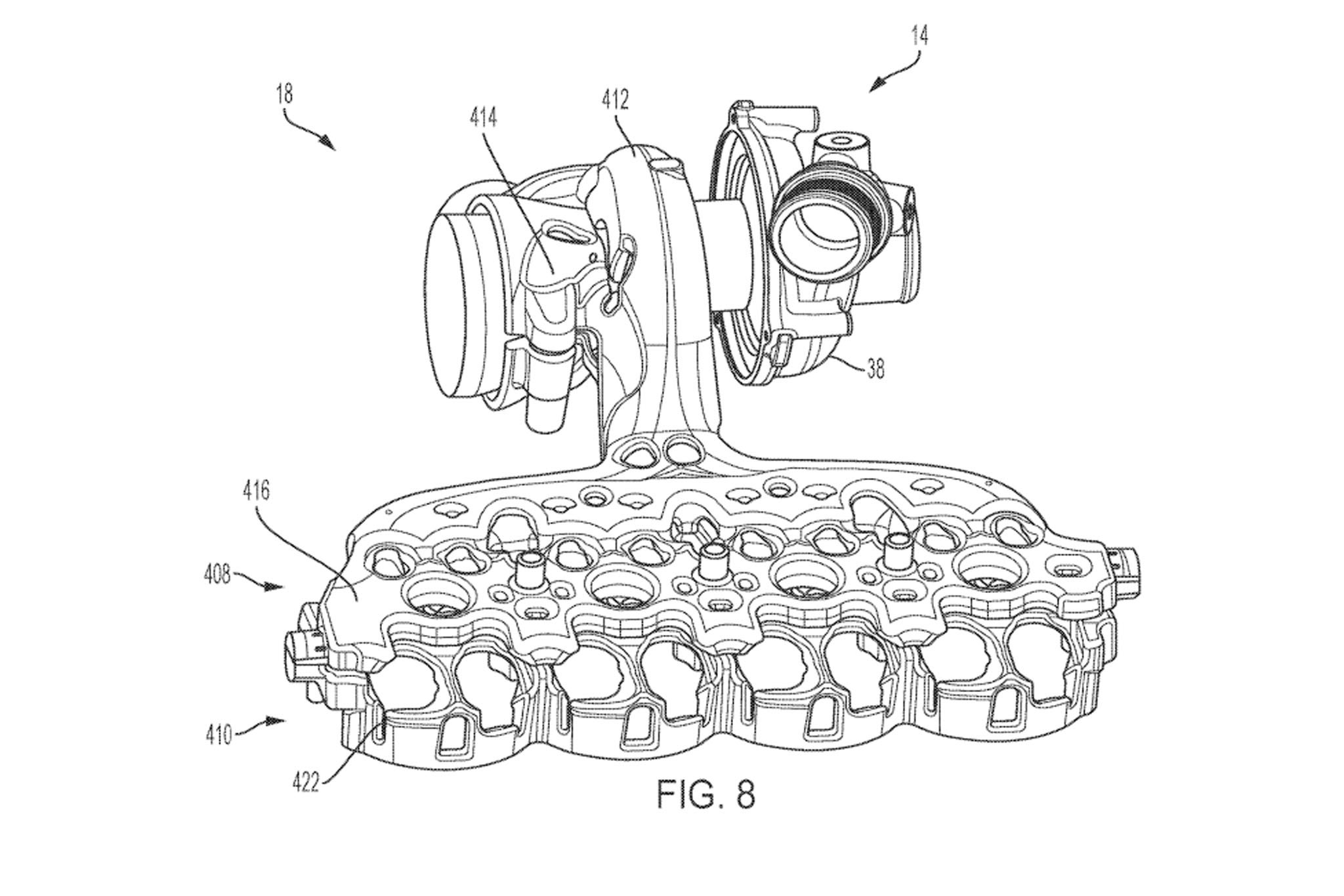

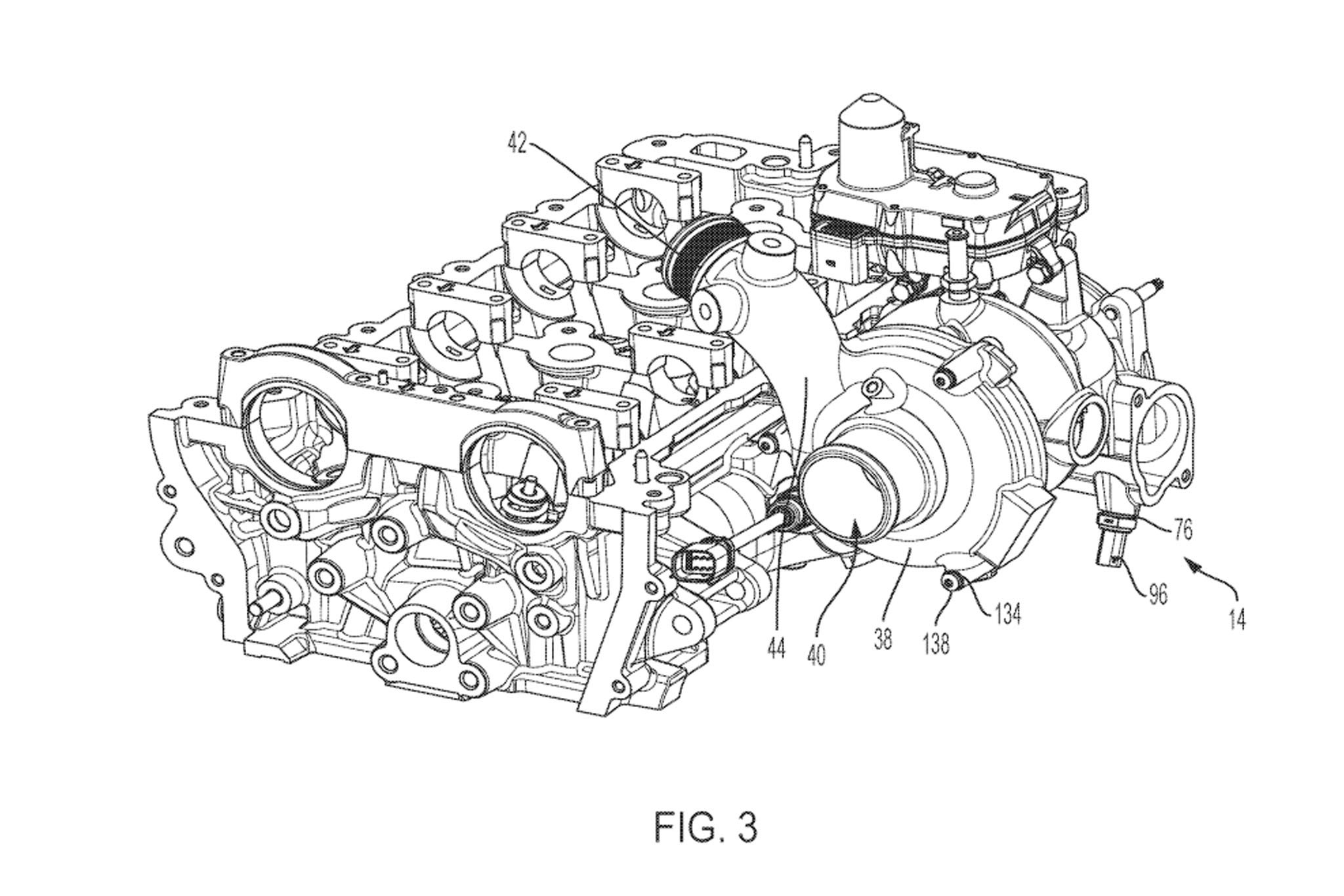

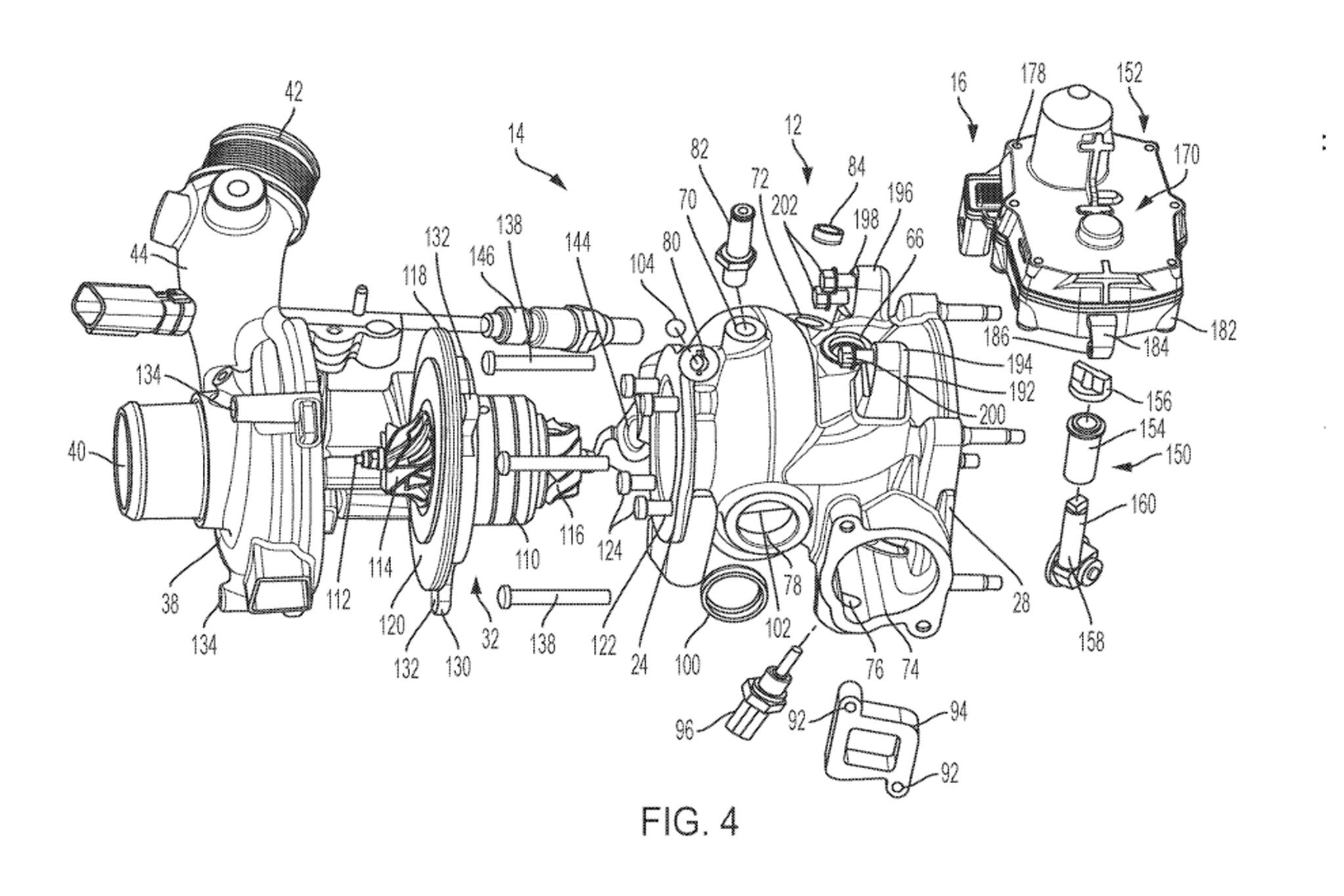

The exhaust manifold is, of course, cast in, as is the exhaust housing. It goes a lot further than that, though. The document notes that parts like the wastegate, or at least a place to mount the moving parts of a wastegate, can be cast directly into place, as can parts of the compressor side of the turbo. The core of the turbocharger—the bearings, shaft, turbine, and compressor wheel themselves—are part of a separate cartridge.

It would require an entire new cylinder head design, manifold, turbo, etc., to do an upgrade. Hybrids would become very difficult if you can not access the turbo without removing the cylinder head. Even if you do remove the cylinder head, then what?

This is much more involved than the cylinder head integrated manifold we see on B58 motors. OEM's would also likely love making turbo upgrades much more difficult.

The aftermarket always finds a way but things are sure getting tougher.

vBulletin Message