Results 1 to 25 of 25

-

10-18-2010, 11:09 AM #1

New Turbo Tech: Borg Warner EFR Turbochargers

New Turbo Tech: Borg Warner EFR Turbochargers

I think all you boost junkies will like this.

I was doing my daily check over at www.Twinturbo.net and found somebody talking about these new turbos being released by Borg Warner in 2011.

http://www.twinturbo.net/nissan/300z...re-coming.html

They will be revealed at SEMA on November 2nd.

I've seen this before, but this is the first mainstream aftermarket offering that I'm aware of. Much lighter than inconel by about half. Titanium Aluminide turbine wheels are OEM on the Mitsu Evo 10

Other items that are noteworthy:

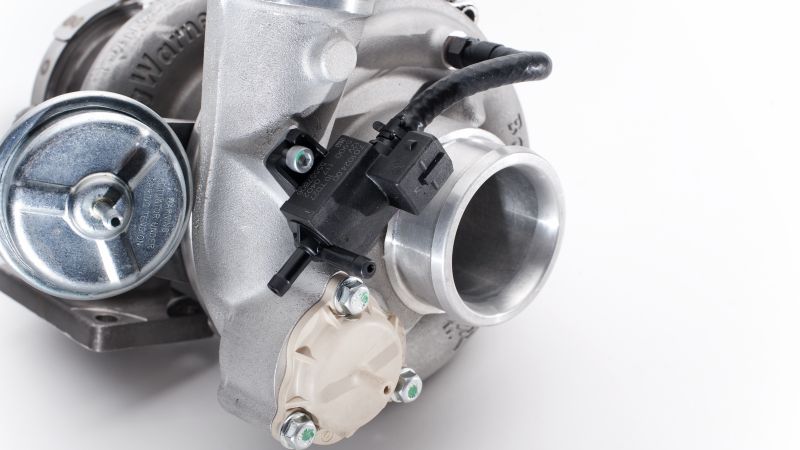

Optional integrated recirc valve in the compressor cover. This has been done by OEM's before, but hasn't been offered as an aftermarket option that I'm aware of

Optional built in Boost Control solenoid

A large internal wastegate that doesn't suck. Somehow they've managed to do internal gating that doesn't involve 90 degree turns like the Garrett turbos do, and is supposed to perform every bit as well as an external gate.

They are offering a GT2860RS and a GT3071R-WG equivalent IN A T25 FLANGE, as well as other T3 and T4 offerings

I should have side by side pics of the GT3071R-WG and its Borg Warner equivalent later this week. FWIW, I'm told the 67mm BW compressor wheel outflows the Garret 71mm wheel despite being smaller, and has much better surge and pressure ratio capability. The 62mm wheel supposedly flows between the Garret 2860 and 3071, but spools faster than either.

Downside: The V-band turbine housing is 3/4" longer than a comparable Garrett housing. This means that the driver side will very likely have clearance issues with the firewall. A new manifold will likely be necessary. So...I wouldn't consider these a bolt on affair by any means.

These will be officially unveiled at SEMA Nov 2. Specs might be released this week, pending patent approval.

Spools quicker, flows better and is just all around more efficient, sounds good to me!

Here is a link to a more detailed article with some really interesting info, pictures and video: http://www.full-race.com/articles/bo...fr-turbos.html

-

10-18-2010, 11:14 AM #2

Here are two pieces of information that I think are really good news, especially considering how modern ECU's operate.

EFR turbo compressor housings incorporate an integrated BOV. Yes, you read that right - the BOV is a recirculating style *built-in* to the Compressor Housing. The major performance advantage in this design is that it redirects the high-pressure compressed air from the outlet of the compressor wheel -> right at the low-pressure inlet of the turbo. This helps to keep the turbo spooled between shifts and offers cost savings/convenience while keeping MAF-based engine mgt happy. With this in place, there is no need for a BOV or flange on the charge piping. Of course for the hardcore racers who want to use an external traditional BOV, the EFR line up has that as well.

For applications which use electronic boost control, an Electronic Boost Control Solenoid (EBCS) is integrated into the compressor housing. This solenoid is truly OEM quality and uses an industry standard fuel injector plug, making it easy to connecting to multiple boost control systems. Of course if the hardcore racers want to use an external solenoid OR a manual boost controller (without the integrated EBCS), that is very easy to do.

-

10-18-2010, 11:15 AM #3

2007 335i Coupe

Mods: Check the Garage

-

10-18-2010, 12:28 PM #4

Guest Vendor

Guest Vendor

- Join Date

- Feb 2010

- Location

- OH

- Posts

- 1,454

- Mentioned

- 2 Post(s)

- Rep Power

- 0

-

10-18-2010, 02:42 PM #5

so who is putting this on an n54?

-

10-18-2010, 02:52 PM #6

Awesome read thanks Slicktop!

Some people live long, meaningful lives.

Other people eat shit and die.

I'm not racist, I hate everybody equally; especially fat people.

-

10-18-2010, 03:03 PM #7

I'm thinking one of the twin-scroll Borg Warner 3071 equivalent could be easily swapped onto the N55. You can even get it with the electronic actuator and integrated recirc port, which I believe is how the N55 stock turbo is set up.

It would make GREAT power, and spool VERY quick. Ceramic bearings, latest tech compressor wheel, titanium aluminide turbine and a stainless steel turbine housing which causes a higher temperature split (driving force) across the turbine with less wasted heat....... things could get very interesting.

-

10-18-2010, 03:35 PM #8Burger Motorsports

Home of the Worlds fastest N20s, N54s, N55s, S55s, N63s, and S63s!

It is the sole responsibility of the purchaser and installer of any BMS part to employ the correct installation techniques required to ensure the proper operation of BMS parts, and BMS disclaims any and all liability for any part failure due to improper installation or use. It is the sole responsibility of the customer to verify that the use of their vehicle and items purchased comply with federal, state and local regulations. BMS claims no legal federal, state or local certification concerning pollution controlled motor vehicles or mandated emissions requirements. BMS products labeled for use only in competition racing vehicles may only be used on competition racing vehicles operated exclusively on a closed course in conjunction with a sanctioned racing event, in accordance with all federal and state laws, and may never be operated on public roads/highways. Please click here for more information on legal requirements related to use of BMS parts.

-

10-19-2010, 03:37 AM #9

-

11-03-2010, 10:34 AM #10

-

11-03-2010, 12:50 PM #11

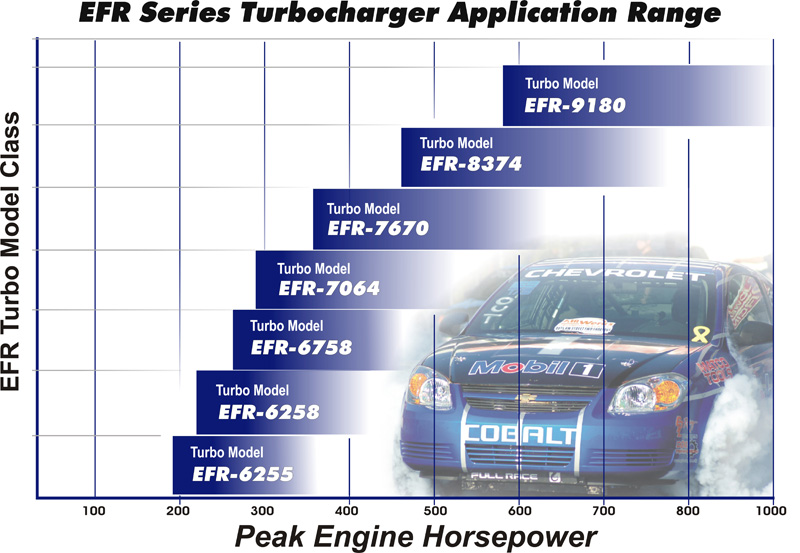

The two model numbers of interest for my 300zx are the EFR 6258 (GT2860RS equivalent) and the EFR 6758 (GT3071R-WG equivalent). Two EFR 6758 should be good for around 900whp and have excellent spool and driveablility!

They are both externally the same dimensions...don't recall if this is the 62mm or the 67mm turbos here. Both have a 58mm turbine wheel, in case you didn't figure out the naming convention.

.64 A/R turbine housing in case anyone is curious.

-

11-03-2010, 12:51 PM #12

-

11-03-2010, 12:59 PM #13

Some more interesting info:

The most exciting technology in the EFR package is the low inertia Gamma-Ti Turbine Wheel. All EFR turbine wheels are made from a high performance lightweight material known as "Gamma-Ti". This material innovation is not quite metal and not quite ceramic, it is considered an "inter-metallic compound". Comprised primarily of titanium and aluminum (titanium-aluminide) with other trace elements, the Gamma-Ti turbine wheel is so light it's nearly the same weight as the forged-machined aluminum compressor wheel. This approximate 1:1 turbine:compressor weight ratio dramatically improves turbo response. Further strength benefits are realized at high temperatures as Gamma-Ti gains ductility and exhibits very high stiffness-to-weight ratios with good vibration damping characteristics. The EFR debut marks the first time Gamma-Ti has been offered to the public across a range of turbine wheel sizes and at an enthusiast's price point.

EFR Gamma-Ti Turbine wheels come in six sizes: 55mm, 58mm, 64mm, 70mm, 74mm, and 80mm OD (turbine inducer diameter) and utilize the latest generation Fullback/Superback turbine wheel blade aero designs specifically tailored for high turbine efficiency and high flow at elevated boost levels. The fullback wheel hubs employ a full aerodynamic back-disk, meaning that the hubline extends all the way to the inlet tip. This feature allows for incredibly smooth (low energy loss) guidance of exhaust flow out of the housing and into the blade channels. Going one step further, the Superback shape adds a curved profile to the backdisk and effectively lowers centrifugal stresses - improving stability at elevated rotational speeds. Impossible in the past due to material stress limitations, the combination of Gamma-Ti and the exciting new .fullback/superback. design works in concert to allow best possible efficiency, high speed capability and durability.

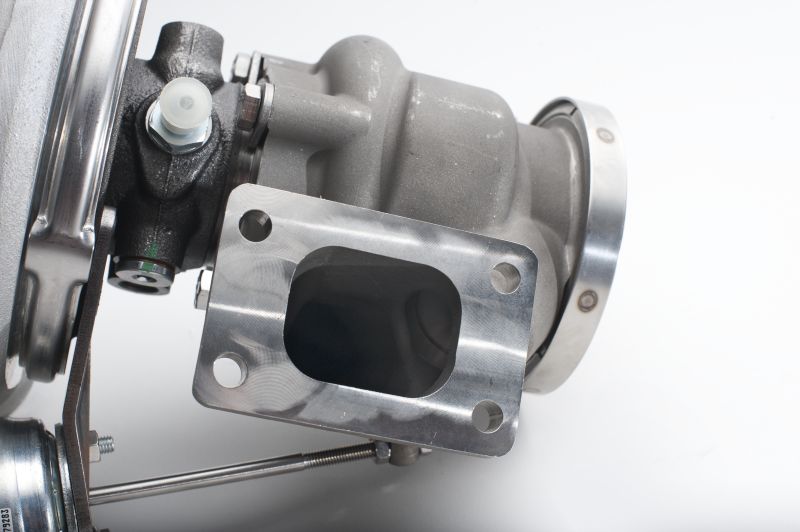

There are (4) investment cast stainless steel turbine housings that make up the initial release of the EFR series (with more to come). Sizes are available in .64 A/R T25, 0.83 A/R T3 and 0.92 A/R internal WG or 1.05 A/R external WG T4 twinscroll footprints, all use a 3" Vband outlet. Stainless steel is a superior material choice for manifolds and turbine housings in turbocharged engines which operate at extreme EGTs. From a performance standpoint, the combination of material properties and thinly cast wall thickness allow less heat energy to escape AND are lighter weight while also being more crack resistant. The investment casting process results in a perfectly smooth surface finish that resembles a ported/polished cyl head and serves to lower gas friction losses - all while looking beautiful in the engine bay (a perfect compliment to the Full-Race header it's attached to). Stainless Turbine housings offer exceptional corrosion resistance at elevated temperatures - far superior to rusty/corroded cast iron housings we are used to seeing in the past. These turbine housings are truly fit for street use, road racing, or even endurance racing and when polished they look like modern-artwork.

NOTE: These are NOT designed to be direct bolt-in replacement turbine housings for other mfg turbos so do NOT expect them to bolt up to your car/manifold without changes unless stated.

The optional EFR internal wastegate is truly designed for high flow, even for big-power setups. EFR optional internal wastegates are aerodynamically-optimized to offer the same performance as an external wastegate recirculated back into the downpipe - no 90 degree corners here. This is a real "value" feature of the EFR program, particularly in the case of twinscroll applications which require (2) external wastegates, (2) manifold wastegate ports (2) dumptubes for maximum performance. Furthermore, the manifold fabrication and installation are both simplified with the wastegated EFR models. Boost levels can be easily adjusted by swapping adjustable wastegate canisters available in three different spring rates/boost levels. Lastly, different turbo clocking positions are easy to accomodate without changing the wastegate bracket. This is because the bracket is bolted to the bearing housing backing plate - not to the compressor housing as is the case with most internal WG turbos. For space constrained applications which can not fit the EFR internal WG or Hardcore racers that want to keep their dual external wastegates mounted to the exhaust manifold - you can do that too!

All EFR turbochargers use Extended Tip Forged Milled Compressor Wheels ***AKA Billet Compressor Wheels*** The six EFR compressor wheels range from 62mm OD (~50mm inducer) to 91mm OD (~67mm inducer). These Extended Tip Technology designs are unique in that they are BorgWarner's highest-boost capable wheel designs yet still produce outstanding map width and flow capacity for efficiency at all boost levels and engine types. EFR compressor wheels are manufactured from forged aluminum for maximum strength and light weight, then CNC machined on a 6-axis CNC Mill. The blade geometry utilizes State-of-the-Art aerodynamics that delivers efficiency, boost capability and surge limits beyond any turbo we have ever seen. The forging strength exceeds that of typical aluminum billet bar-stock and also exceeds the material properties of an aluminum lost-wax compressor wheel casting. These compressors define .top shelf. in terms of strength, efficiency, range/width, and of course pressure ratio (boost) capability.

-

11-03-2010, 01:04 PM #14

These are some very tasty turbos!

There are three compressor housing sizes and types - All housings come with the same features BOV, BSCV, V-band connection, hose clamp surfaces, etc. The first is a small compressor housing for the T25 turbos. The medium is used with the mid-sized 70mm and 76mm OD compressor wheels available. The large compressor housing is used with the 83mm and 91mm wheels. Lastly, exclusive to the large cover is a dual-machined outlet, useful for both a hose connection and/or a v-band connection. If the v-band feature is needed, the hose connection portion can be cut off and discarded. Full-Race will offer vband 90 degree bends for applications which require a tight bend, close to the turbo (such as RB26 and many subaru rotated setups). The medium and large housings both use an inlet recirculation groove (AKA ported shroud) for maximum compressor map width and anti-surge characteristics.

Speed sensor mounting provisions are also supplied on every compressor cover (speed sensors are sold separately). Turbo speed sensors are not new technology, but the installation procedure has always been difficult for even the most experienced tuners/installers. Traditionally the customer must remove their compressor cover and take it to a machinist. This machinist then has to set up the cover at a compound angle to precisely drill the speed sensor bore while carefully hitting the contour area of the wheel bore at the right angle. The BorgWarner EFR solution provides this precision machining already done to every compressor cover. The hole stops short of protruding into the compressor wheel bore. If a user decides to buy a speed sensor as an upgrade accessory, they simply remove the compressor cover and extend the hole the rest of the way through to the wheel bore using a hand drill. A ¼" drill bit is used and the length required to be drilled is quite short. This hole allows the tip of the sensor to come flush with the contour surface. The hole does not have to be precise, as no sealing takes place in the small hole that the user just created.

All EFR turbochargers use high-end Ceramic Ball Bearings for Enhanced Turbo Response -- Even though BorgWarner has been known as a long-time manufacturer of high end journal bearing turbos, the engineering team developed ceramic ball bearing cartridges for the uncompromising EFR series. EFR bearing cartridges house dual-row ceramic balls in special alloy bearing races to provide substantial friction reduction. The biggest benefits of ball bearings are most clearly realized at low turbo shaft speeds (spool-up region) and they also help improve turbocharger response/boost recovery as found between gear shifts. Once the engine is at full boost, ball bearings offer no advantage in performance - BUT - there are huge performance benefits for getting up to the desired boost level FAST and delivering quick throttle response for on-off-on-off aggressive driving. From a durability standpoint, the EFR cartridge bearing system provides a huge increase in thrust load capacity over conventional systems and requires much less oil supply. From a fuel efficiency standpoint, parasitic loss is reduced at low turbo speed so MPG increases can be realized. Lastly, the EFR bearing system includes the latest in turbo seal technology reducing oil seepage/burning problems often found in aftermarket installations (more on this later!!)

EFR bearing housings have the option for water-cooling. Water cooling is recommended where possible to do so, but not mandatory. If watercooling is not connected, be sure to use clean, high viscosity synthetic oil (15W) and do not repeatedly perform "hot engine shutdowns".

A properly sized "restrictor" aka oil metering orifice is integrated into the bearing housing so EXTERNAL OIL RESTRICTORS SHOULD NOT BE ADDED TO EFR TURBOS. A -4AN male fitting has been provided on the EFR turbo and a -4AN (¼") line is recommended. Oil return is tapped to 3/8NPT as well as 2 bolt flange comaptible.

EFR Summary

The BorgWarner EFR turbo is set to become the new world standard for performance turbocharging due to the high-technology feature package, unbeatable performance, and installation convenience. The EFR turbocharger was designed and manufactured with only one purpose in mind: to dominate the street, track, and strip. (7) different sized turbos, optimally matched for the 250-1000hp per turbo segment - and in (4) different turbine housings are the result. The combination of this top-shelf geometry and the Gamma-Ti turbine wheel significantly raises the bar for performance aftermarket turbochargers. Combined with our ball bearing technology, it is the most responsive range or turbos that are available anywhere, at any price. The EFR series covers all applications except the hardcore drag racers. For those hardcore customers, we still offer the highly popular S400SX and S500SX product lines, and will continue to update those turbos during the next year.

-

11-03-2010, 05:10 PM #15

-

11-03-2010, 05:33 PM #16

-

11-03-2010, 06:14 PM #17

-

11-04-2010, 07:05 PM #18

Holy $#@! these turbos really are the $#@!!! Integrated speed sensor ports, I WANT!! This is the mother of all data!

Some people live long, meaningful lives.

Other people eat shit and die.

I'm not racist, I hate everybody equally; especially fat people.

-

11-06-2010, 10:44 PM #19

Member

Member

- Join Date

- Aug 2010

- Location

- Strong Island

- Posts

- 3,432

- Rep Points

- 3,063.0

- Mentioned

- 101 Post(s)

- Rep Power

- 31

-

11-16-2010, 03:32 PM #20

Member

Member

- Join Date

- Oct 2010

- Posts

- 885

- Rep Points

- 8.0

- Mentioned

- 1 Post(s)

- Rep Power

- 0

They are awesome but I wouldn't expect to see these on anything with packaging concerns. They are BIG turbos (not wheel-size!). The solenoid is just a solenoid, not an actuator - it still requires a pressure-referenced mechanical wastegate, it just has a solenoid built in (not really that big of a feature considering a GM solenoid is ~$15 and dead reliable). The built in recirc BOV is nice, as is the built in IWG, but the whole package is likely to be priced at $2000+ for any of the 500 hp+ units and they do not conform to garrett/precision standard footprints, so serious custom work will be involved. Even the turbine discharge is very very different.

-

11-22-2010, 01:14 AM #21

Member

Member

- Join Date

- Nov 2010

- Posts

- 3

- Rep Points

- 4.3

- Mentioned

- 0 Post(s)

- Rep Power

- 0

-

11-22-2010, 01:15 AM #22

-

11-22-2010, 01:26 AM #23

Member

Member

- Join Date

- Nov 2010

- Posts

- 3

- Rep Points

- 4.3

- Mentioned

- 0 Post(s)

- Rep Power

- 0

Nah, it's not stupid at all.

But for the people who are already setup (at great expense usually) with a T3 manifold and a Garrett style single scroll turbine housing and O2 housing, and single external wastegate - Those people could simply swap in one of these new BWs without starting all over on all that other stuff. And actually on my car, I would not only have to start over on all those things, I would also probably have to relocate the oil filter and alternator (on the DSM).

-

11-22-2010, 01:41 AM #24

-

11-22-2010, 01:58 AM #25

Member

Member

- Join Date

- Nov 2010

- Posts

- 3

- Rep Points

- 4.3

- Mentioned

- 0 Post(s)

- Rep Power

- 0

Yes that's mostly it, but also, the Garrett standard, especially the T31 style (4 bolt outlet with 2.5 inch outlet diameter) is very nice for people who need a compact installation and compact routing of the exhaust out of the turbine housing.

With these BW housings, they have used a 3" V-band outlet all the way down to the smallest turbos in the range. These smaller turbos have a turbine exducer diameter of about 2 inches. For the diameter of the outlet to jump from 2" to 3" instantly as it leaves turbine wheel is not necessary and is not even good from the CFD standpoint. Not user friendly if you need to turn a corner quickly with your exhaust piping immediately after leaving the turbine - this could be much more compact with 2.5" diam outlet.

I don't want to detract from the rest of the turbo though. I do think that the turbos overall are a step ahead of everything else.Last edited by Mr Mitsu; 11-22-2010 at 02:03 AM.

Quote

Quote

Welcome Haldi,...

Let's point and laugh at Haldi